Welding Procedures and Welders Qualifications

Preview on WPS, PQR & WPQ

WPS — Welding Procedure Specification

A Welding Procedure Specification (WPS) is a detailed written document that provides technical instructions for performing a specific weld.

It defines the exact parameters and conditions needed to ensure consistent, repeatable, and compliant welds.

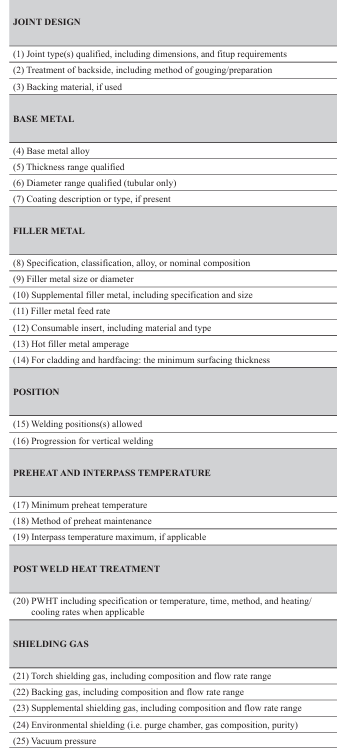

Key details included in a WPS:

- Positions and thickness ranges qualified

- Welding process (GTAW, GMAW, PAW)

- Base metals and filler materials

- Joint design and preparation

- Shielding gases and flow rates

- Amperage, voltage, and travel speed

- Preheat and post-weld heat treatment requirements

Example of Variables on the WPS According to D17.1

Procedure Qualification Record (PQR)

A Procedure Qualification Record (PQR) is a formal document required by AWS D17.1 Aerospace Welding Specification that provides objective evidence proving that a Welding Procedure Specification (WPS) is capable of producing welds that meet the required quality standards.

The PQR captures actual welding parameters, test results, and inspection data from test coupons welded under controlled conditions. It demonstrates that the WPS has been validated through destructive and nondestructive testing in accordance with AWS standards.

Why the PQR Is Important?

In aerospace and defense manufacturing, welding quality is critical. The PQR is essential for main reasons:

1. Compliance with AWS D17.1 / NADCAP / Prime Specifications.

- Aerospace primes such as Boeing, Lockheed Martin, Gulfstream, and RTX require validated WPSs supported by qualified PQRs.

- It is a mandatory requirement for NADCAP AC7110/12 and AWS standards.

2. Objective Evidence of Weld Quality

- The PQR verifies that a procedure produces defect-free welds on specific base materials, joint types, and thickness ranges.

- It records actual test results including:

- Visual inspection

- Dye penetrant testing (PT)

- Radiographic testing (RT / X-ray)

- Destructive tests.

- This ensures the procedure meets AWS D17.1 Class A, or B acceptance criteria.

3. Builds Confidence with Aerospace Customers & Auditors

- The PQR provides traceable, audit-ready documentation showing your company follows controlled, repeatable processes.

- Customers and prime contractors expect a complete PQR package linked to every WPS.

- Without a qualified PQR, companies risk:

- Audit findings

- Contract noncompliance with aerospace primes

- Costly rework and delays

Welder Performance Qualification (WPQ)

A Welder Performance Qualification (WPQ), also referred to as a Welder Qualification Test (WQT), is a formal certification process that verifies a welder’s ability to produce sound, defect-free welds in accordance with a qualified Welding Procedure Specification (WPS).

Under AWS D17.1 (aerospace welding standards), welders must pass a practical welding test using the exact materials, joint configurations, processes, and parameters defined in the WPS. The resulting test coupons are then inspected and tested — both visually and through nondestructive testing — to confirm compliance with Class A/B/C acceptance criteria.

Benefits of WPQ Certification

1. Ensures Welder Competency

- Confirms the welder can consistently produce high-quality welds.

- Tests proficiency in specific welding processes

- Verifies capability on aerospace-grade materials like aluminum, titanium, stainless steel, Inconel, and nickel alloys.

2. Reduces Risk of Weld Defects

- WPQ testing simulates production conditions, ensuring welders follow the qualified WPS correctly.

- Properly certified welders help prevent costly rework, scrap, and part failures.

- Ensures that welds meet tight aerospace tolerances and prime contractor specifications.

3. Builds Customer Confidence & Compliance Traceability

- Provides audit-ready records linking each welder to the WPS and PQR they are qualified under.

- Demonstrates to customers and auditors that your company:

- Uses certified welders

- Follows controlled, repeatable processes

- Produces welds that meet AWS D17.1 Class A/B/C criteria

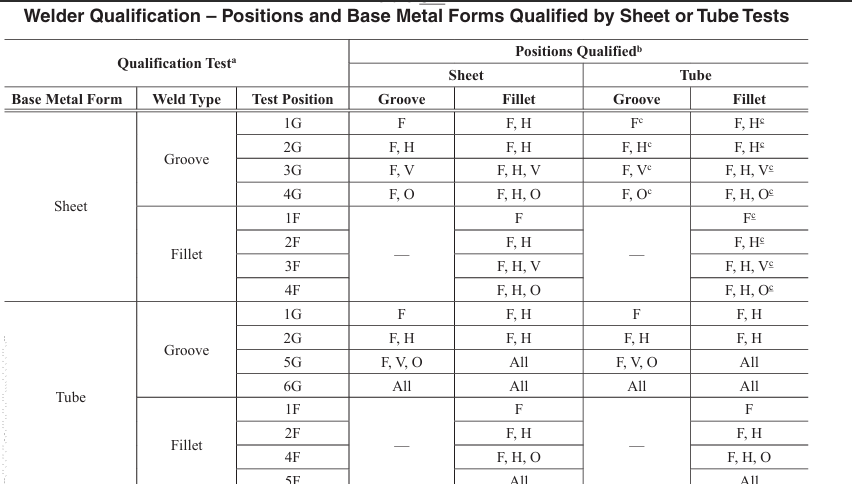

Welders Qualifications – Positions and Base Metal Forms in accordance with to D17.1